Mobile Welding Explained: When Fabrication Avails to Your Workplace

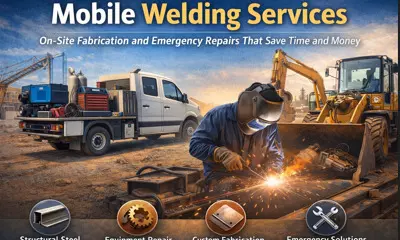

Discover how mobile welding services provide on-site fabrication, structural steel repairs, and emergency welding solutions to reduce downtime and costs.

How mobile welding brings a full-service fabrication shop directly to your job site for faster, safer, and cost-effective results.

Mobile welding takes the services of a complete welding shop to your workplace. This will offer professional fabrication and mending where it is required.

Rather than transporting heavy machinery, structural steel, or oversized parts to a remote place, mobile welding companies can come to your place with all the equipment and knowledge necessary to complete the task within a relatively short period and with a lot of efficiency. The method has gained more importance in any industry where idle time is very expensive, and transportation is not viable.

What Is Mobile Welding?

Mobile welding refers to the activity of making welding and fabrication in the field, using portable welding tools that are loaded on a service vehicle or a rig. The mobile welders come with generators, welding machines, torches, gases, and safety equipment. In fact,t a kind of workshop on its own which can work in different conditions such as construction sites and farms, industrial facilities, and remote areas. Contrary to traditional shop welding,g where raw materials are transported to a permanent plant and welding is done in a common place, mobile welders require no transportation of large or immovable objects. This saves on time, logistics hustles and projects do not remain stalled.

Why On-Site Welding Matters

Convenience is considered to be one of the best things about mobile welding. The machinery, heavy equipment, and structural components are not easily movable,e and taking them to a shop to get welded might not be feasible or safe. It is solved by mobile welding,g which brings skilled welders and portable machines to the areas of work and saves time and effort.

Mobile welding may be notably essential in case of an emergency. In the event of machinery failure, a structural support or unforeseen damage, the availability of a welder on-site is beneficial since work can commence without costly downtime wasted, and operations will be back on track.

Modifiability and Adaptability

Mobile welders receive training onsite to deal with a variety of tasks and materials, such as:

Structural steel welding

Repairs on machinery and equipment.

Custom metal fabrication

On-site changes and modifications.

They can fit in special job demands and react to the changing conditions at the workplace. It can be heavy steel, stainless steel, aluminum, or any other metal, but mobile welders come with all the appropriate equipment and expertise to accomplish a wide variety of projects most cost-effectively.

Cost and Time Savings

Mobile welding is very cost-effective. By removing the transportation, labor, and possible damage during transportation of the heavy equipment, or the deconstructing of the building in order to perform the off-site welding, businesses save on transportation and labor. The reduced number of delays will imply fewer workflow disruptions and subsequent rapid recovery to full productivity. Mobile welding services have been known to be less overhead intensive as compared to the traditional workshops. The welders do not need a permanent facility, and therefore, they can provide competitive prices but not compromise on quality. This ease of use, fast turnaround, coupled with reduced costs make mobile welding a solution of interest to many business enterprises.

Safety and On-Site Expertise

Mobile welding is also safer. Carrying heavy or damaged machinery to a shop may pose some risks in the loading, shipping, and unloading processes. Working on-site will allow the welders to evaluate the risks on-site and take safety precautions that will be unique to the work environment. The professional mobile welders are equipped with protective equipment and are well informed on the safety standards in the industry, so that they do their work in best quality without compromising on the safety equipment.

Conclusion

Mobile welding is a growing industry in most industries, especially in construction, farming, manufacturing, marine, and infrastructure. Mobile welding can offer an effective and convenient alternative to the conventional shop services, whether it be on-site structural fabrication or an emergency solution to a repair that is required in a remote location. It is flexible, hence businesses can handle the welding demands at any time and from any place.